Plating

めっき加工

Nickel plating

Nickel plating has characters such as hard, good color and protection of corrosion. This process is widely applied for anti-corrosion, decoration and primary coating of chrome and precious metal plating process.

Tin Plating

Tin is a relatively soft metal and tin plating is applied to moving parts and glands of machinery. It also has good solderability and excellent electric conductivity and is applied to electric contacts, terminals and connectors.

Tin-Zinc Plating

This plating has 15-30% zinc dispersed in tin. The plating film is soft and does not easily crack or peel off when bent or riveted, and has excellent secondary processing properties such as solderability.

Silver Plating

Silver is the best electric and heat conductive metal and silver plating is widely applied to electric contacts and terminals.

Gold Plating

Gold is extremely chemically stable metal and has high anti-corrosive nature. It also has excellent electric and heat conductivity and low connection resistance. Gold plating is increasingly applied to electronic and electric parts.

Zinc Plating

Zinc is widely used as the anti-rusting coating of iron. Zinc plating plus trivalent chrome plating increases corrosion durability. Choice of yellow, black or clear color zinc plating is available and this process is best applied for decoration and distinguishing purposes.

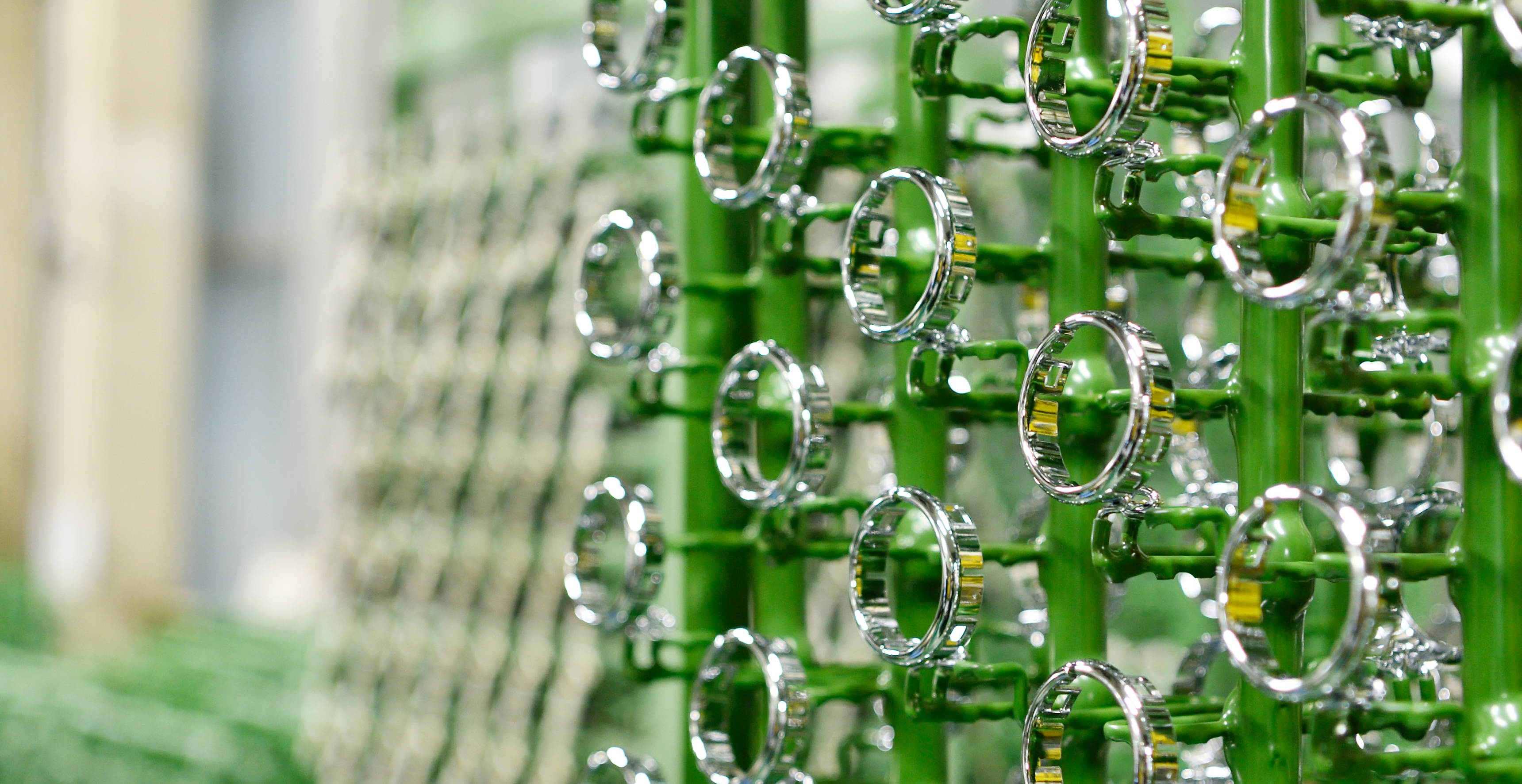

Nickel-Chrome Plating

Chrome plating over the three layers of half-shiny, tri-chrome and shiny nickel plating gives excellent anti-corrosion and decorative characters. This process is widely applied to such automotive parts as seat belts, shift levers and door fittings.

Plastic Plating

Metal plating gives plastic parts beautiful metallic appearance and heat protection. Plastic parts of ABS, PCABS and PPO can be metal plated. This process is applied to interior and exterior parts of automobiles, pachinko parts, water faucet parts, etc.

Satin plating

Our satin plating is a semi-glossy aluminum-like plating with a luxurious look that is also used for the interior and exterior of automobiles.

It is widely used, mainly for the interiors of major automobile manufacturers.

We also offer satin plating in combination with two-color molding. We offer integrated production from molding (single color/two-color) to satin plating.

Plastic Molding

樹脂成形加工

Insert Molding

Insert molding is to set pressing parts inside mold in advance and spout plastic materials around parts. We introduce the insert robot system for the stable quality and production.

Plastic Molding

Our long-time accumulated technique to give beautiful metal appearance to the products made by ABS, PCABS PPO, etc. This process is also available to multi-use plastic parts, engineering plastics, etc.

Double-Molding

Plastic molding with dissimilar materials such as ABS and Pori-Carbonated in the same process is available. To use materials of different nature (plating and anti-plating nature) provides plating without masking, to reduce assembling process and to expand variation of decoration. We can propose variety of products using ‘double-molding’ and ‘plastic plating’.